Payment Type: T/T

Transportation: Ocean

$8900

≥1 Set/Sets

Brand: JLD

Types Of: Laminating Machine

Applicable Industry: Manufacturing Plant

Out-of-warranty Service: Video Technical Support, Field Maintenance And Repair Service, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Pakistan, Kazakhstan, Algeria, India, Viet Nam, Kenya, Mexico, Russia, Nigeria, South Korea, Bangladesh, South Africa, Thailand, Indonesia, Germany

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Pakistan, Nigeria, South Korea, Bangladesh, Uzbekistan, India, Viet Nam, South Africa, Philippines, Russia, Brazil, Peru, Thailand, Colombia, Kenya, Indonesia, Germany

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Motor, Gearbox

Status: New

Application: Machinery &Amp; Hardware

Type Of Packaging: Film

Packaging Materials: Plastic

Degree Of Automation: Automatic

Power Type: Electric

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: High-Accuracy

| Selling Units | : | Set/Sets |

|---|---|---|

| Package Type | : | standard |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

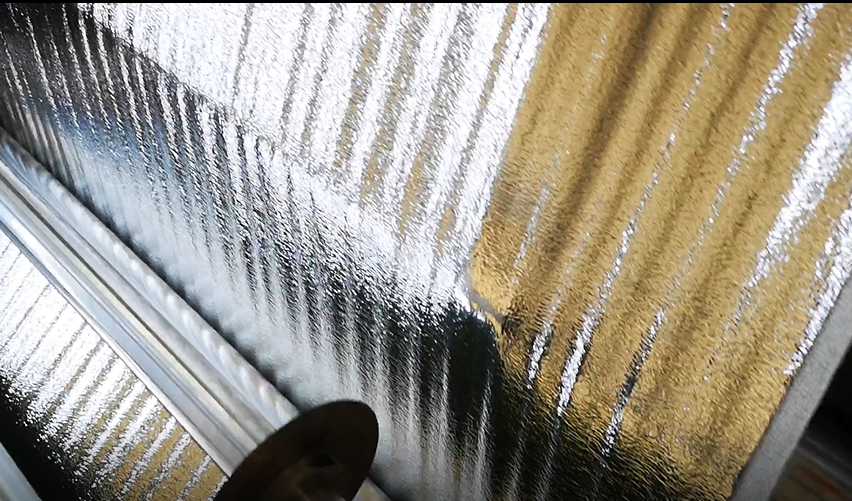

The HOT OIL Laminating Machine is a cutting-edge device designed to enhance the quality of laminated materials. With its advanced technology, this machine provides a seamless and efficient laminating process. It offers a wide range of functions, including precise temperature control, adjustable pressure, and automatic feeding. Its hot oil system ensures even heat distribution, resulting in a smooth and bubble-free lamination. The HOT OIL laminating machine also boasts a high production capacity, allowing for fast and uninterrupted operation. With its exceptional performance and user-friendly interface, this machine is the perfect choice for achieving professional and flawless laminated products.

The colorful PE film pattern you can customization as you wish.The bonding machine can make two layers EPE foam sheet together,and you can repeat this operation,you can get the final thickness you want.If the thickness over than 50MM,You'd better use a horizontal bonding machine.when the EPE sheet get the thickness of you need.next you need the Epe Foam Automatic Cutting Machine cut the bonded EPE foam sheet to the right size.the cutting machine controlled by the Siemens PLC system,Simple operation and high accuracy.The last step use the recycling machine to melt the waste EPE foam edge,It can be continuously reused and recycled indefinitely.

Packaging: standard

Transportation: Ocean

Place of Origin: China

Supply Ability: 100 SETS per month

Certificate: ce

Port: QINGDAO

Payment Type: T/T

Incoterm: FOB

Hot Products

SEND INQUIRY