Payment Type: T/T

Transportation: Ocean

$18000-25000 /Set/Sets

| Maximum pipe diameter | |

| Contact Now |

Brand: JLD

Applicable Industry: Manufacturing Plant

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Viet Nam, Russia, South Korea, South Africa

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Viet Nam, Russia, Colombia, Kyrgyzstan

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Motor

Old And New: New

Species: Pipe Welding Machine

Pipe Material: Pe

Application: Drain Pipe

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

| Selling Units | : | Set/Sets |

|---|---|---|

| Package Type | : | nude cargo |

The file is encrypted. Please fill in the following information to continue accessing it

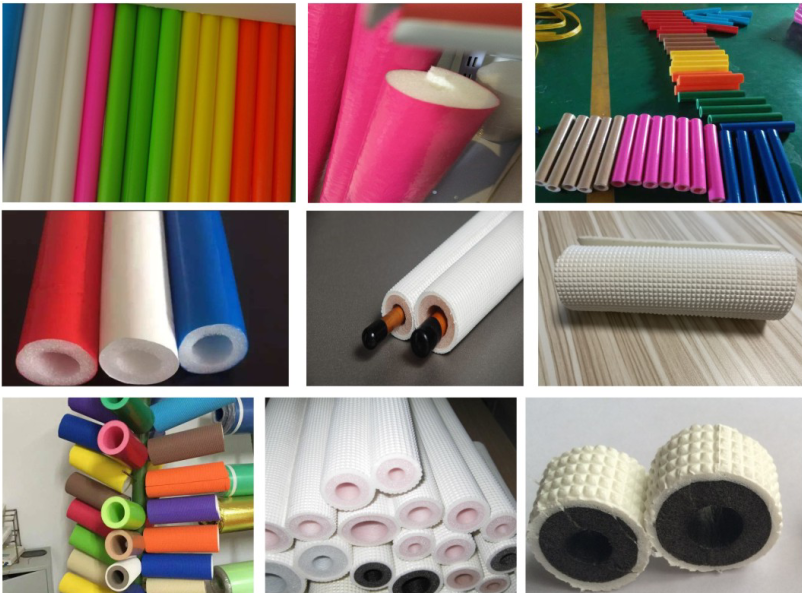

XPE Pipe welding/making machine

The XPE tube welding machine is the device to weld XPE sheet in pipe shape, it is also called XPE insulation pipe making machine or XPE foam pipe bonding machine. And before welding , you may need to coat the XPE sheet with colorful film, so you will need a XPE Laminating & bonding machine.

This machine is mainly used to roll the sliced XPE or PEF foam sheets into tubes and weld the joints.The pieces can also be coated to the outer surface of the foam pipe and weld the contact surface and joints to make xpe tubes.

Main technical parameters

1. Put a roll frame.

2. Reinding pipe welding part:

a. 3 hot air guns, air pump air;

b.Mold (match according to customer requirements)

c. One tension frame;

d. One set of traction devices

Traction motor adopts cycloidal needle wheel motor, frequency conversion speed regulation; two conveyor belts, to ensure sufficient friction, the upper conveyor belt can be manually lifted, easy to adjust the adjustment of pipe traction force.

3. One fixed-length Cutting Machine

a. A pair of variable frequency speed control traction rollers, the upper roller can be manually lifted, easy to adjust the traction force of the double stick on the tube;

b. The disc knife, pneumatic lifting;

c. Automatic meter counting, automatic cutting.Length is free to be set.

4. One set of conveyor belt devices can transport the cut pipe out.

Main technical parameters

a. speed: 8-15m / min

b. Total power: about 9kw

c. The coil diameter is 20-120mm

5.Overall dimension: 10m*1.2m*2.2m

Packaging: nude cargo

Productivity: 10

Transportation: Ocean

Place of Origin: shandong

Supply Ability: 10

Certificate: CE

Port: qingdao

Payment Type: T/T

Incoterm: FOB,FCA

Hot Products

SEND INQUIRY