Payment Type: T/T

Transportation: Ocean,Land

$18920

≥1 Set/Sets

| Model | |

| Maximum pipe diameter | |

| Contact Now |

Model No.: JGJ100

Brand: JLD

Applicable Industry: Manufacturing Plant

Out-of-warranty Service: Video Technical Support, Field Maintenance And Repair Service, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Saudi Arabia, Kenya, Algeria, Kazakhstan, Tajikistan, Bangladesh, Nigeria, Uzbekistan, South Africa, Uae, Mexico, Brazil, Peru, Russia, Morocco, Colombia, Ukraine, Kyrgyzstan, Argentina

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Algeria, Kazakhstan, Tajikistan, Uzbekistan, Kyrgyzstan, South Korea, Russia, Philippines, Viet Nam, Chile

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Pump

Old And New: New

Species: Pipe Welding Machine

Pipe Material: Pe

Application: Energy Supply Pipe

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic

| Selling Units | : | Set/Sets |

|---|---|---|

| Package Type | : | safety exporting package |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

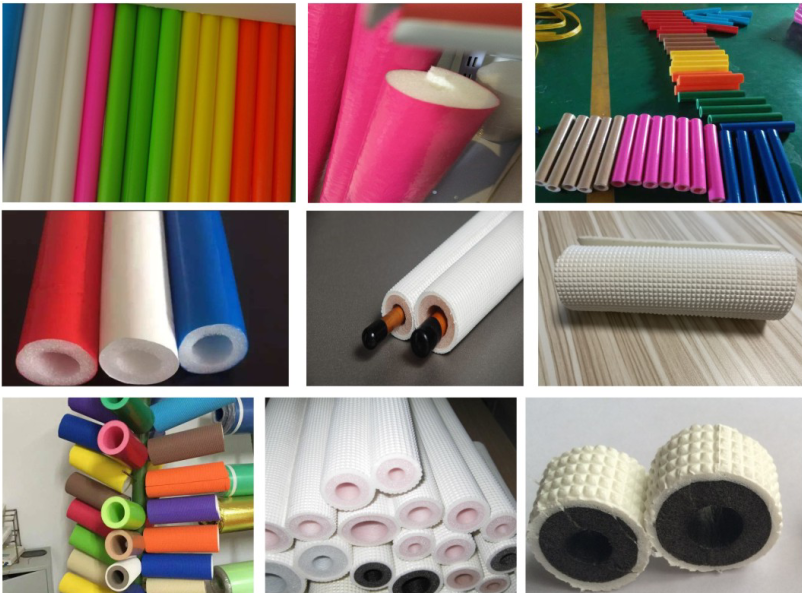

Air condition insulation pipe making machine

The air condition insulation pipe making machine is a specialized equipment designed to manufacture insulation pipes used in air conditioning systems. It is capable of producing pipes with excellent thermal insulation properties, ensuring efficient cooling and heating performance.

The machine operates by feeding raw materials, such as polyethylene or polyurethane foam, into a designated area where they are melted and shaped into a cylindrical form. The molten material is then extruded through a die, which gives the pipe its desired dimensions and shape.

For making air condition insulation pipe,except the pipe welding machine,you still need one set of epe foam pipe extruding machine, to make epe foam pipes,and then,you need a set of XPE laminating and bonding machine to laminate PE film on the XPE foam sheet,after that ,you need use the slitting machine to slit the wide XPE foam sheet into narrow foam sheet,at last,you will use the pipe welding machine to weld the narrow xpe sheet cover on the surface of the epe foam pipes,then the insulation pipe is finished.

And if you have EPE Foam Machine,such as EPE Foam Sheet Extrusion Making Line,you can make all kinds of different width and thickness of EPE foam sheet rolls,and after that,you can use hot oil Laminating Machine or Laminating Extrusion Machine to laminate all kinds of materials with EPE foam rolls.And if you want to get thicker epe foams,you can use PE Bonding Machine to bond many layers of epe foams togather,the pe bonding machine have two types,one is Vertical Bonding Machine and another is Horizontal Bonding Machine,you can choose as your requirement.

If you have any question,pls welcome to contact us.

Application of the Air condition insulation pipe making machine

About our factory of epe foam machine

Packaging: safety exporting package

Productivity: 10-30 meters per minute

Transportation: Ocean,Land

Place of Origin: CHINA

Supply Ability: 100 sets per month

Certificate: CE ISO9001

Port: Qingdao port

Payment Type: T/T

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA

Hot Products

SEND INQUIRY